- 網站首頁

- 廣西產品中心

- 工程案例

- 關于睿馳

-

頭條動態

-

西安睿馳古建材料有限公司2025年春節放假通知

01-28 more

-

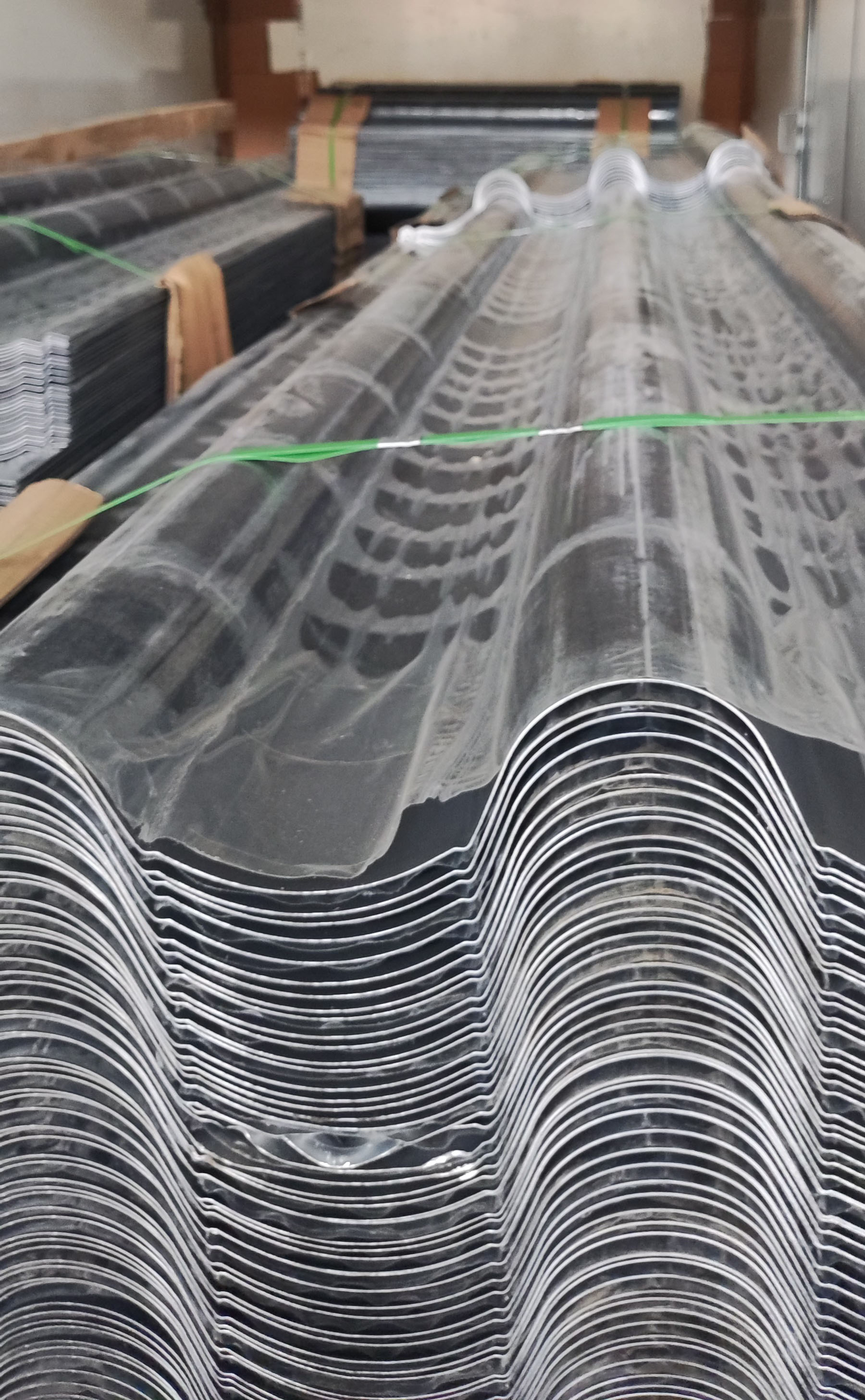

多功能連體鋁瓦供應商:中式屋面一站式解決方案

11-29 more

-

高品質仿古金屬瓦制造商,為您打造卓越屋頂

08-22 more

-

親身感覺中式酒店_售樓部金屬瓦屋面改造航拍效果

05-21 more

-

連體鋁瓦行業品牌推薦

04-20 more

-

高端金屬瓦傳承、守護歷史文脈建設古風新韻交融

04-01 more

-

連體鋁瓦解決傳統瓦片易損壞的問題

03-06 more

-

西安睿馳古建材料有限公司2024年春節放假通知

02-04 more

-

西安睿馳古建材料有限公司2025年春節放假通知

-

聯系我們

當前位置:

當前位置:

熱門推薦

熱門推薦